Hello Everyone,

I am sorry for not posting anything lately. I would like to wish everyone a belated Merry Christmas and a Happy New Year. I will be posting new articles after the New Year. Meanwhile, please follow my activity on Twitter and facebook. Thank you very much for your support.

Regards,

Engineerblogger

Wednesday 28 December 2011

Monday 19 December 2011

7 things you may not know about catalysis

Engineerblogger

Dec 19, 2011

Catalysts are all around us.

Catalysts are one of those things that few people think much about, beyond perhaps in high school chemistry, but they make the world tick. Almost everything in your daily life depends on catalysts: cars, Post-It notes, laundry detergent, beer. All the parts of your sandwich—bread, cheddar cheese, roast turkey. Catalysts break down paper pulp to produce the smooth paper in your magazine. They clean your contact lenses every night. They turn milk into yogurt and petroleum into plastic milk jugs, CDs and bicycle helmets.

What is catalysis?

Catalysts speed up a chemical reaction by lowering the amount of energy you need to get one going. Catalysis is the backbone of many industrial processes, which use chemical reactions to turn raw materials into useful products. Catalysts are integral in making plastics and many other manufactured items.

Even the human body runs on catalysts. Many proteins in your body are actually catalysts called enzymes, which do everything from creating signals that move your limbs to helping digest your food. They are truly a fundamental part of life.

Small things can have big results.

In most cases, you need just a tiny amount of a catalyst to make a difference. Even the size of the catalyst particle can change the way a reaction runs. Last year, an Argonne team including materials scientist Larry Curtiss found that one silver catalyst is better at its task when it's in nanoparticles just a few atoms wide. (The catalyst turns propylene into propylene oxides, which is the first step in making antifreeze and other products.)

It can make things greener.

Industrial manufacturing processes for plastic and other essential items often produce nasty by-products which can pose hazards to human health and the environment. Better catalysts can help solve that problem. For example, the same silver catalyst actually produces fewer toxic by-products—making the whole reaction more environmentally friendly.

At its heart, a catalyst is a way to save energy. And applying catalysts on a grand scale could save the world a lot of energy. Three percent of all of the energy used in the U.S. every year goes into converting ethane and propane into alkenes, which are used to make plastics, among other things. That's the equivalent of more than 500 million barrels of gasoline.

Catalysts are also the key to unlocking biofuels. All biomass—corn, switchgrass, trees—contains a tough compound called cellulose, which has to be broken down to make fuel. Finding the perfect catalyst to disintegrate cellulose would make biofuels cheaper and more viable as a renewable energy source.

Often, we have no idea why they work.

The precise reasons why catalysts work are often still a mystery to scientists. Curtiss works in computational catalysis: using computers to tackle the complicated interplay of physics, chemistry and math that explains how a catalyst operates.

Once they've figured out the process, scientists can try to build a catalyst that works even better by simulating how different materials might work instead. Potential configurations for new catalysts can run to thousands of combinations, which is why supercomputers are best at dealing with them.

When Edison was building the lightbulb, he tested literally hundreds of different filaments (likely testing the patience of his lab assistants as well) before discovering the carbonized filament. By taking advantage of supercomputers and modern technology, scientists can speed up the years of testing and expense to get to breakthroughs.

Curtiss runs simulations on Argonne's Blue Gene/P supercomputer to design possible new catalysts. "As supercomputers have gotten faster, we've been able to do things we'd never have been able to do 10 years ago," he said.

They could be essential for the next big revolution in batteries.

Newly efficient lithium-ion batteries helped turn clunky car phones into the slim, elegant cell phones and laptops available today. But scientists are already searching for the next revolution in batteries—one that could someday make a battery light and powerful enough to take a car 500 miles at a go. A promising idea is lithium-air batteries, which use oxygen from the air as a primary component. But this new battery will require totally revamping the internal chemistry, and it will need a powerful new catalyst to make it work. A lithium-air battery works by combining lithium and oxygen atoms and then breaking them apart, over and over. That is a situation tailor-made for a catalyst, and a good one would make the reaction faster and make the battery more efficient.

How do you make a new catalyst?

Understanding the chemistry behind reactions is the first step; then scientists can use modeling to design potential new catalysts and have them tested in the lab. But that first step is difficult unless you can get down to the atomic level to see what is happening during a reaction. This is where big scientific facilities like Argonne's Advanced Photon Source (APS) shine. At the APS, scientists can use the brightest X-rays in the United States to track the reactions in real time. At the laboratory's Electron Microscopy Center, researchers take photos of the atoms while they react. Curtiss and the team have used both of these in their search for better catalysts.

Source: Argonne National Laboratory (ANL)

Dec 19, 2011

Catalysts are all around us.

Catalysts are one of those things that few people think much about, beyond perhaps in high school chemistry, but they make the world tick. Almost everything in your daily life depends on catalysts: cars, Post-It notes, laundry detergent, beer. All the parts of your sandwich—bread, cheddar cheese, roast turkey. Catalysts break down paper pulp to produce the smooth paper in your magazine. They clean your contact lenses every night. They turn milk into yogurt and petroleum into plastic milk jugs, CDs and bicycle helmets.

What is catalysis?

Catalysts speed up a chemical reaction by lowering the amount of energy you need to get one going. Catalysis is the backbone of many industrial processes, which use chemical reactions to turn raw materials into useful products. Catalysts are integral in making plastics and many other manufactured items.

Even the human body runs on catalysts. Many proteins in your body are actually catalysts called enzymes, which do everything from creating signals that move your limbs to helping digest your food. They are truly a fundamental part of life.

Small things can have big results.

In most cases, you need just a tiny amount of a catalyst to make a difference. Even the size of the catalyst particle can change the way a reaction runs. Last year, an Argonne team including materials scientist Larry Curtiss found that one silver catalyst is better at its task when it's in nanoparticles just a few atoms wide. (The catalyst turns propylene into propylene oxides, which is the first step in making antifreeze and other products.)

It can make things greener.

Industrial manufacturing processes for plastic and other essential items often produce nasty by-products which can pose hazards to human health and the environment. Better catalysts can help solve that problem. For example, the same silver catalyst actually produces fewer toxic by-products—making the whole reaction more environmentally friendly.

At its heart, a catalyst is a way to save energy. And applying catalysts on a grand scale could save the world a lot of energy. Three percent of all of the energy used in the U.S. every year goes into converting ethane and propane into alkenes, which are used to make plastics, among other things. That's the equivalent of more than 500 million barrels of gasoline.

Catalysts are also the key to unlocking biofuels. All biomass—corn, switchgrass, trees—contains a tough compound called cellulose, which has to be broken down to make fuel. Finding the perfect catalyst to disintegrate cellulose would make biofuels cheaper and more viable as a renewable energy source.

Often, we have no idea why they work.

The precise reasons why catalysts work are often still a mystery to scientists. Curtiss works in computational catalysis: using computers to tackle the complicated interplay of physics, chemistry and math that explains how a catalyst operates.

Once they've figured out the process, scientists can try to build a catalyst that works even better by simulating how different materials might work instead. Potential configurations for new catalysts can run to thousands of combinations, which is why supercomputers are best at dealing with them.

When Edison was building the lightbulb, he tested literally hundreds of different filaments (likely testing the patience of his lab assistants as well) before discovering the carbonized filament. By taking advantage of supercomputers and modern technology, scientists can speed up the years of testing and expense to get to breakthroughs.

Curtiss runs simulations on Argonne's Blue Gene/P supercomputer to design possible new catalysts. "As supercomputers have gotten faster, we've been able to do things we'd never have been able to do 10 years ago," he said.

They could be essential for the next big revolution in batteries.

Newly efficient lithium-ion batteries helped turn clunky car phones into the slim, elegant cell phones and laptops available today. But scientists are already searching for the next revolution in batteries—one that could someday make a battery light and powerful enough to take a car 500 miles at a go. A promising idea is lithium-air batteries, which use oxygen from the air as a primary component. But this new battery will require totally revamping the internal chemistry, and it will need a powerful new catalyst to make it work. A lithium-air battery works by combining lithium and oxygen atoms and then breaking them apart, over and over. That is a situation tailor-made for a catalyst, and a good one would make the reaction faster and make the battery more efficient.

How do you make a new catalyst?

Understanding the chemistry behind reactions is the first step; then scientists can use modeling to design potential new catalysts and have them tested in the lab. But that first step is difficult unless you can get down to the atomic level to see what is happening during a reaction. This is where big scientific facilities like Argonne's Advanced Photon Source (APS) shine. At the APS, scientists can use the brightest X-rays in the United States to track the reactions in real time. At the laboratory's Electron Microscopy Center, researchers take photos of the atoms while they react. Curtiss and the team have used both of these in their search for better catalysts.

Source: Argonne National Laboratory (ANL)

Posted by

Unknown

1 comments

Fuel Cells: A Clean Energy Alternative at New World Trade Center, New York City’s Octagon

CleanTechnica

Dec 18, 2011

Our posting of UTC Power’s February 2011 infographic comparing the energy conversion and green tech attributes of their 400 kilowatt (kW) model PureCell with that of the equivalent solar and wind power systems generated a number of comments and criticism.

Looking to clarify matters and respond to readers’ comments, including adding information about the infographic’s underlying assumptions and data sources, I got back in touch with UTC Power’s marketing and communications manager Mike Glynn with the help of the MSL Group’s Mary McCeney. I believe it pays to keep an open mind when considering clean, green energy alternatives.

In the process, I learned about two high-profile applications of UTC Power’s PureCell fuel cell systems. First, 12 UTC Power PureCell Model 400 fuel cell stacks are now on site at the new World Trade Center in downtown New York City. Providing 4.8 megawatts (MW) of clean power when operational, the combined systems will rank as one of the largest fuel cell installations in the world, according to UTC.

In a second installation, solar and fuel cell power are both providing clean energy at The Octagon, a mixed-use residential and commercial building complex on Roosevelt Island in midtown Manhattan. A 50kW solar power array and a PureCell Model 400, 400kW system are supplying 50% of the building’s power needs.

To read more click here...

Dec 18, 2011

|

| Photo courtesy UTC Power |

Our posting of UTC Power’s February 2011 infographic comparing the energy conversion and green tech attributes of their 400 kilowatt (kW) model PureCell with that of the equivalent solar and wind power systems generated a number of comments and criticism.

Looking to clarify matters and respond to readers’ comments, including adding information about the infographic’s underlying assumptions and data sources, I got back in touch with UTC Power’s marketing and communications manager Mike Glynn with the help of the MSL Group’s Mary McCeney. I believe it pays to keep an open mind when considering clean, green energy alternatives.

In the process, I learned about two high-profile applications of UTC Power’s PureCell fuel cell systems. First, 12 UTC Power PureCell Model 400 fuel cell stacks are now on site at the new World Trade Center in downtown New York City. Providing 4.8 megawatts (MW) of clean power when operational, the combined systems will rank as one of the largest fuel cell installations in the world, according to UTC.

In a second installation, solar and fuel cell power are both providing clean energy at The Octagon, a mixed-use residential and commercial building complex on Roosevelt Island in midtown Manhattan. A 50kW solar power array and a PureCell Model 400, 400kW system are supplying 50% of the building’s power needs.

To read more click here...

Posted by

Unknown

0

comments

Labels:

Fuel Cell,

Green Energy,

Infrastructure,

United States

Japan's Sony generates power from paper

Engineerblogger

Dec 19, 2011

Japanese electronics giant Sony on Thursday revealed technology that generates electricity from shredded paper.

As an environmental products fair opened in Tokyo, Sony invited children to put paper into a mixture of water and enzymes, shake it up and wait for a few minutes to see the liquid become a source of electricity, powering a small fan.

"This is the same mechanism with which termites eat wood to get energy," said Chisato Kitsukawa, a public relations manager at Sony.

While academic research has previously taken place on this kind of power generation, proof-of-concept demonstrations are rare, he said.

The performance was part of Sony's drive to develop a sugar-based "bio battery" that turns glucose into power.

Shredded paper or pieces of corrugated board were used at the fair to provide cellulose, a long chain of glucose sugar found in the walls of green plants.

Enzymes are used to break the chain and the resulting sugar is then processed by another group of enzymes in a process that provides hydrogen ions and electrons.

The electrons travel through an outer circuit to generate electricity, while the hydrogen ions combine with oxygen from the air to create water.

"Bio batteries are environmentally friendly and have great potential" as they use no metals or harmful chemicals, Kitsukawa said.

But the technology is a long way from commercial viability because of its low power output. It is currently sufficient to run digital music players but not powerful enough to replace commonly used batteries, he said.

Sony first unveiled test sugar battery technology in 2007 and has since reduced the battery's size into a small sheet.Another sugar battery was on display at the fair embedded in a Christmas card, which played music when drops of fruit juice were added to it.

Source: AFP

Dec 19, 2011

Japanese electronics giant Sony on Thursday revealed technology that generates electricity from shredded paper.

As an environmental products fair opened in Tokyo, Sony invited children to put paper into a mixture of water and enzymes, shake it up and wait for a few minutes to see the liquid become a source of electricity, powering a small fan.

"This is the same mechanism with which termites eat wood to get energy," said Chisato Kitsukawa, a public relations manager at Sony.

While academic research has previously taken place on this kind of power generation, proof-of-concept demonstrations are rare, he said.

The performance was part of Sony's drive to develop a sugar-based "bio battery" that turns glucose into power.

Shredded paper or pieces of corrugated board were used at the fair to provide cellulose, a long chain of glucose sugar found in the walls of green plants.

Enzymes are used to break the chain and the resulting sugar is then processed by another group of enzymes in a process that provides hydrogen ions and electrons.

The electrons travel through an outer circuit to generate electricity, while the hydrogen ions combine with oxygen from the air to create water.

"Bio batteries are environmentally friendly and have great potential" as they use no metals or harmful chemicals, Kitsukawa said.

But the technology is a long way from commercial viability because of its low power output. It is currently sufficient to run digital music players but not powerful enough to replace commonly used batteries, he said.

Sony first unveiled test sugar battery technology in 2007 and has since reduced the battery's size into a small sheet.Another sugar battery was on display at the fair embedded in a Christmas card, which played music when drops of fruit juice were added to it.

Source: AFP

Posted by

Unknown

0

comments

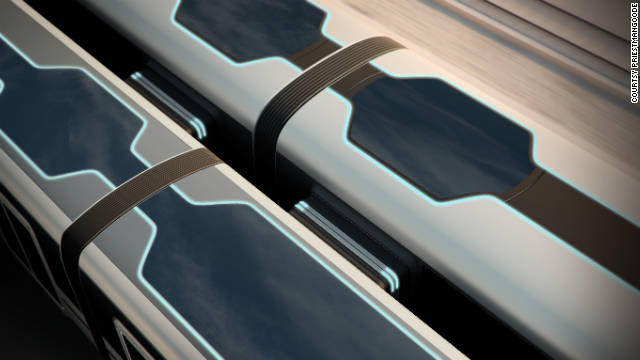

Boarding a moving train: The way to speed up rail travel?

Engineerblogger

Dec 19, 2011

A designer has come up with a unique and futuristic solution for speeding up rail travel: he doesn't want to change the engines, or the tracks -- he wants to get rid of the stations.

Determined to take rail transport into the 21st century, Paul Priestman, director of British design group Priestmangoode, is the man behind the "Moving Platforms" concept, which he believes could potentially revolutionize the rail industry.

His scheme would see travelers served by a carousel of trams and high-speed trains that would take passengers from their homes to their destinations without them ever having to use a bus, car or taxi.

"The idea with Moving Platforms is that ... if you were going on holiday or on business for instance, you could get onto a tram on your street and then seamlessly travel from that onto the high-speed line and then get off at your destination in another city, then onto a tram and then end up at your destination without ever having gone in your car or perhaps got on a bus," says Priestman.

"It's totally integrated into a sort of larger transport system," he adds.

The idea is to have a city-wide network of trams that travel in a loop and connect with a high-speed rail service.

But instead of passengers having to get off the tram at a rail station and wait for the next HSR service to arrive, the moving tram would "dock" with a moving train, allowing passengers to cross between tram and train without either vehicle ever stopping.

"The trams speed up and the high-speed train slows down and they join, so they dock at high speed," explains Priestman.

"They stay docked for the same amount of time that it would stop at a station," he adds.

"There are big doors, there are wide doors, they're all the same level so you can seamlessly go between the two vehicles quite peacefully; there's no hurry.

"Then, when everyone's done that, the doors shut and then the trains separate and the tram then goes back into the city or town and picks up more passengers and drops off passengers."

Instead of using paper tickets to pass through a barrier, passengers would used an RFID (radio-frequency identification) system to transfer from tram to train. Similar systems that let passengers scan pre-paid smartcards are already used on many public transport networks.

While Priestman admits that it will be some time before his vision could be implemented, he says the time has come to rethink how we travel.

"This idea is a far-future thought but wouldn't it be brilliant to just re-evaluate and just re-think the whole process?" he says.

Source: CNN

Related Information:

Dec 19, 2011

|

| The 'Moving Platforms' concept envisions city-wide tram networks that are integrated with a high-speed rail service. Credit: CNN |

A designer has come up with a unique and futuristic solution for speeding up rail travel: he doesn't want to change the engines, or the tracks -- he wants to get rid of the stations.

Determined to take rail transport into the 21st century, Paul Priestman, director of British design group Priestmangoode, is the man behind the "Moving Platforms" concept, which he believes could potentially revolutionize the rail industry.

His scheme would see travelers served by a carousel of trams and high-speed trains that would take passengers from their homes to their destinations without them ever having to use a bus, car or taxi.

"The idea with Moving Platforms is that ... if you were going on holiday or on business for instance, you could get onto a tram on your street and then seamlessly travel from that onto the high-speed line and then get off at your destination in another city, then onto a tram and then end up at your destination without ever having gone in your car or perhaps got on a bus," says Priestman.

"It's totally integrated into a sort of larger transport system," he adds.

The idea is to have a city-wide network of trams that travel in a loop and connect with a high-speed rail service.

But instead of passengers having to get off the tram at a rail station and wait for the next HSR service to arrive, the moving tram would "dock" with a moving train, allowing passengers to cross between tram and train without either vehicle ever stopping.

"The trams speed up and the high-speed train slows down and they join, so they dock at high speed," explains Priestman.

"They stay docked for the same amount of time that it would stop at a station," he adds.

|

| Credit: CNN |

"Then, when everyone's done that, the doors shut and then the trains separate and the tram then goes back into the city or town and picks up more passengers and drops off passengers."

Instead of using paper tickets to pass through a barrier, passengers would used an RFID (radio-frequency identification) system to transfer from tram to train. Similar systems that let passengers scan pre-paid smartcards are already used on many public transport networks.

While Priestman admits that it will be some time before his vision could be implemented, he says the time has come to rethink how we travel.

"This idea is a far-future thought but wouldn't it be brilliant to just re-evaluate and just re-think the whole process?" he says.

Source: CNN

Related Information:

Posted by

Unknown

0

comments

Can motors in wheels spark electric car revolution?

Engineerblogger

Dec 19, 2011

There may have been more alluring electric cars on display at this year's Tokyo Motor Show, but the beauty of this prototype lies in its performance.

The SIM-LEI can travel 333 kilometers (more than 200 miles) on a single charge, say its Japanese creators SIM Drive, and it also boasts supercar-like acceleration -- 0 to 60 mph in just 4.8 seconds.

The key to these remarkable statistics lies not, as you might expect, underneath the hood but in its wheels.

Most electric vehicles house a single motor in the area vacated by the petrol engine, but the SIM-LEI has four motors, which fit in the hubs its wheels.

Each one delivers 65 kilowatts, giving the car a total output of 260 kilowatts, compared with the 80 kilowatts of output available in, say, the Nissan Leaf.

A 24.5 kWh battery sits below the floor along with inverters and controllers, which fit into a unique steel monocoque helping reduce weight, according to SIM Drive.

The SIM-LEI -- LEI stands for Leading Efficiency In-Wheel motor -- took 15 months to complete and builds on advances made with the fantastic-looking Eliica -- a super-fast eight-wheeler designed by SIM Drive CEO and President Hiroshi Shimizu.

His latest design may not look so sporty but the SIM LEI does come with low-friction tires and a low-set chassis, which helps reduce drag, says the company.

Recent technological advances are making in-wheel motors more attractive, says James Widmer, from the Center for Advanced Electrical Drives at the UK's Newcastle University.

"Motors have become more powerful for their weight and the volume they take up, which has made it more practical to get very good performance from putting electric motors directly in the wheels of cars," Widmer said.

And electric motors provide drivers with far greater control than internal combustion engines, he says.

"If you do put an electric motor in each wheel then there are huge possibilities with things like traction control and stability control," he added.

While car makers including Peugeot and Mitsubishi have used in-wheel motors in concept cars that have never been commercially available, SIM Drive hopes its four-seat sedan will go into production in 2013.

SIM Drive says the price will depend on how many it makes, but if the car ends up being mass produced, customers can expect to pay around ¥2.5 million ($32,000).

Source: CNN

Dec 19, 2011

|

| The SIM-LEI electric car can travel 333 kilometers on a single charge, say its creators. |

There may have been more alluring electric cars on display at this year's Tokyo Motor Show, but the beauty of this prototype lies in its performance.

The SIM-LEI can travel 333 kilometers (more than 200 miles) on a single charge, say its Japanese creators SIM Drive, and it also boasts supercar-like acceleration -- 0 to 60 mph in just 4.8 seconds.

The key to these remarkable statistics lies not, as you might expect, underneath the hood but in its wheels.

Most electric vehicles house a single motor in the area vacated by the petrol engine, but the SIM-LEI has four motors, which fit in the hubs its wheels.

Each one delivers 65 kilowatts, giving the car a total output of 260 kilowatts, compared with the 80 kilowatts of output available in, say, the Nissan Leaf.

A 24.5 kWh battery sits below the floor along with inverters and controllers, which fit into a unique steel monocoque helping reduce weight, according to SIM Drive.

The SIM-LEI -- LEI stands for Leading Efficiency In-Wheel motor -- took 15 months to complete and builds on advances made with the fantastic-looking Eliica -- a super-fast eight-wheeler designed by SIM Drive CEO and President Hiroshi Shimizu.

His latest design may not look so sporty but the SIM LEI does come with low-friction tires and a low-set chassis, which helps reduce drag, says the company.

Recent technological advances are making in-wheel motors more attractive, says James Widmer, from the Center for Advanced Electrical Drives at the UK's Newcastle University.

"Motors have become more powerful for their weight and the volume they take up, which has made it more practical to get very good performance from putting electric motors directly in the wheels of cars," Widmer said.

And electric motors provide drivers with far greater control than internal combustion engines, he says.

"If you do put an electric motor in each wheel then there are huge possibilities with things like traction control and stability control," he added.

While car makers including Peugeot and Mitsubishi have used in-wheel motors in concept cars that have never been commercially available, SIM Drive hopes its four-seat sedan will go into production in 2013.

SIM Drive says the price will depend on how many it makes, but if the car ends up being mass produced, customers can expect to pay around ¥2.5 million ($32,000).

Source: CNN

Posted by

Unknown

0

comments

Quantum levitation goes viral

Engineerblogger

Dec 19, 2011

Coat a sapphire disk with a few microns of superconducting ceramic, drop it over some magnets, and watch it float. The seeming miracle is the result of "quantum trapping." That and the hard work of some researchers at Tel Aviv University.

Levitation was once relegated to the realms of mystic texts and mountain top yogis. No longer. Thanks to researchers at Tel Aviv University, Israel, objects in our time can float comfortably in the air, gliding through it friction free or hovering as motionless as a bronze cast of Saint Joseph of Cupertino.

The objects in question are no air hockey pucks, nor are they the finicky, gyroscopic magnets of yester-decade's Levitron. We're talking superconductors--high-transition temperature superconductors.

In the video above, Dr. Boaz Almog, a researcher with Tel Aviv's High Tc Superconductivity Group, can be seen placing a small disk over a magnetic track. There it remains, in whatever orientation he leaves it, centimeters away from the magnets. It does not fly off to the side, repelled by the magnetic field, nor does it skate about willy-nilly when released. When Almog adjusts the disks attitude to a rakish angle, it stays put till touched again. When hit with a flick of a finger it glides over the magnets as if friction were a property of some other universe.

To make the magic happen, Almog and his compatriots, Professor Guy Deutscher and Mishael Azoulay, coated a sapphire disk, the thickness of a business card or two, with a few microns of yttrium barium copper oxide. This ceramic goes superconductor at a mere negative 301°F. Sounds chilly, to be sure, but it's a good 100 degrees warmer than physicists thought was the limit back in the 1980s. In fact, 301 is balmy enough that a good dose of liquid nitrogen can whip the YBCO into superconductivity.

When properly cooled, superconductors do their conducting with zero resistance. They also become averse to all magnetic fields. Usually that's a deal killer for any magnet/superconductor relationship. But thanks to the thinness of Almog's disk, a magnetic field can enter it here and there in the form of "flux tubes." Where they penetrate the disk, superconductivity is locally destroyed. The magnetic field has holes in it and the superconductivity circulates around them, pinning them, and the disk, in place. The effect is strong enough that the disk can hover five centimeters above the magnets, "a world record for levitation of superconductors," says Almog.

The phenomenon is made possible, in part, by the group's initial ignorance of how to grow a superconducting layer. They used a buffer between the YBCO and the sapphire that was thought to be inferior by other researchers. Though their buffer material is less compatible with YCBO than the more common buffer material, it allowed them to grow a thick, mechanically strong, and crack-free film. "It was pure accident," says Almog. "We had this buffer material laying in our lab and we thought, 'What the hell, let's use it.'"

Does all this mean we'll soon be commuting to work on personal quantum levitating hovercrafts? Someday. Maybe. "In principal it would be possible to levitate very heavy objects," says Almog. "If you could stretch our technology to the edge and grow tens of microns of superconductor with a one meter surface you could have a very strong levitation—you'd have to pave your road with magnets. Will it be economical? I'm not sure."

What, then, does one do with a levitating superconductor? "I hoped that from this exposure, someone one would suggest an application," says Almog. "But it didn't happen."

Until someone thinks of something, the piece will remain a curio (one soon available for play in Lancaster, PA, at the North Museum of Science and Natural History. The museum bought one from Almog after he gave a demonstration there). Once again, we have to put our hovercraft dreams in suspension.

Source: American Society of Mechanical Engineers(ASME)

Dec 19, 2011

Coat a sapphire disk with a few microns of superconducting ceramic, drop it over some magnets, and watch it float. The seeming miracle is the result of "quantum trapping." That and the hard work of some researchers at Tel Aviv University.

Levitation was once relegated to the realms of mystic texts and mountain top yogis. No longer. Thanks to researchers at Tel Aviv University, Israel, objects in our time can float comfortably in the air, gliding through it friction free or hovering as motionless as a bronze cast of Saint Joseph of Cupertino.

The objects in question are no air hockey pucks, nor are they the finicky, gyroscopic magnets of yester-decade's Levitron. We're talking superconductors--high-transition temperature superconductors.

In the video above, Dr. Boaz Almog, a researcher with Tel Aviv's High Tc Superconductivity Group, can be seen placing a small disk over a magnetic track. There it remains, in whatever orientation he leaves it, centimeters away from the magnets. It does not fly off to the side, repelled by the magnetic field, nor does it skate about willy-nilly when released. When Almog adjusts the disks attitude to a rakish angle, it stays put till touched again. When hit with a flick of a finger it glides over the magnets as if friction were a property of some other universe.

|

| The disk hovers above the magnets. Credit: ASME |

To make the magic happen, Almog and his compatriots, Professor Guy Deutscher and Mishael Azoulay, coated a sapphire disk, the thickness of a business card or two, with a few microns of yttrium barium copper oxide. This ceramic goes superconductor at a mere negative 301°F. Sounds chilly, to be sure, but it's a good 100 degrees warmer than physicists thought was the limit back in the 1980s. In fact, 301 is balmy enough that a good dose of liquid nitrogen can whip the YBCO into superconductivity.

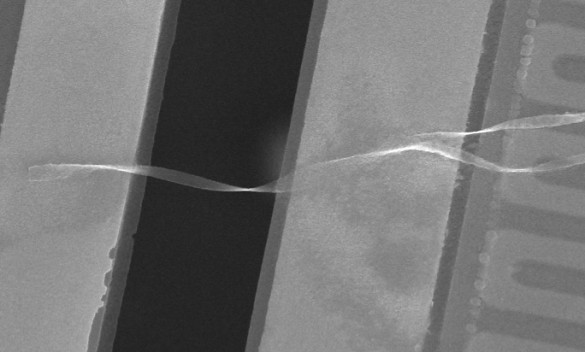

When properly cooled, superconductors do their conducting with zero resistance. They also become averse to all magnetic fields. Usually that's a deal killer for any magnet/superconductor relationship. But thanks to the thinness of Almog's disk, a magnetic field can enter it here and there in the form of "flux tubes." Where they penetrate the disk, superconductivity is locally destroyed. The magnetic field has holes in it and the superconductivity circulates around them, pinning them, and the disk, in place. The effect is strong enough that the disk can hover five centimeters above the magnets, "a world record for levitation of superconductors," says Almog.

The phenomenon is made possible, in part, by the group's initial ignorance of how to grow a superconducting layer. They used a buffer between the YBCO and the sapphire that was thought to be inferior by other researchers. Though their buffer material is less compatible with YCBO than the more common buffer material, it allowed them to grow a thick, mechanically strong, and crack-free film. "It was pure accident," says Almog. "We had this buffer material laying in our lab and we thought, 'What the hell, let's use it.'"

|

| The magnetic field penetrates in the form of quantum flux tubes. |

Does all this mean we'll soon be commuting to work on personal quantum levitating hovercrafts? Someday. Maybe. "In principal it would be possible to levitate very heavy objects," says Almog. "If you could stretch our technology to the edge and grow tens of microns of superconductor with a one meter surface you could have a very strong levitation—you'd have to pave your road with magnets. Will it be economical? I'm not sure."

What, then, does one do with a levitating superconductor? "I hoped that from this exposure, someone one would suggest an application," says Almog. "But it didn't happen."

Until someone thinks of something, the piece will remain a curio (one soon available for play in Lancaster, PA, at the North Museum of Science and Natural History. The museum bought one from Almog after he gave a demonstration there). Once again, we have to put our hovercraft dreams in suspension.

Source: American Society of Mechanical Engineers(ASME)

Posted by

Unknown

0

comments

A Solar Trade War Could Put Us All in the Dark

Technology Review

Dec 19, 2011

The brewing solar trade war between the United States and China sullies what should be a triumphant moment in the global photovoltaic (PV) industry: the arrival of affordable solar electricity.

After decades of global competition and collaboration, many solar markets around the world have reached grid parity—the point at which generating solar electricity, without subsidies, costs less than the electricity purchased from the grid. In other words, solar technology is ready to be a major contributor to solving our planet's energy and environmental crisis.

However, trade protectionism threatens to inhibit the solar industry at the very time when it is breaking through to a new level of global interdependence, collaboration, and maturity.

On October 18, the U.S. government was asked to impose tariffs on imports of Chinese solar cells and modules, based on the argument that China-based producers have been heavily subsidized and are selling solar products at unfairly low prices. Perhaps not surprisingly, some Chinese companies have now asked the Chinese government to impose tariffs on imports of American solar products, arguing that U.S.-based producers have been heavily subsidized, too. And just like that, the production of affordable and competitive solar products has become a political liability in the world's two largest producers and consumers of energy.

The success of the entire solar industry hinges on the success of not one country or one company, but global competition and collaboration, which drives efficiency improvements and cost reductions worldwide. If trade barriers are imposed in the U.S., China, or Germany, it could cause a significant increase in the price of solar products and therefore solar electricity, globally. That could cause a further erosion of political support for the solar industry at a critical juncture.

Altogether, a solar trade war could undermine decades of international innovation and stall the global adoption of advanced solar technology.

To read more click here...

Dec 19, 2011

|

| Credit: Brian Bailey |

The brewing solar trade war between the United States and China sullies what should be a triumphant moment in the global photovoltaic (PV) industry: the arrival of affordable solar electricity.

After decades of global competition and collaboration, many solar markets around the world have reached grid parity—the point at which generating solar electricity, without subsidies, costs less than the electricity purchased from the grid. In other words, solar technology is ready to be a major contributor to solving our planet's energy and environmental crisis.

However, trade protectionism threatens to inhibit the solar industry at the very time when it is breaking through to a new level of global interdependence, collaboration, and maturity.

On October 18, the U.S. government was asked to impose tariffs on imports of Chinese solar cells and modules, based on the argument that China-based producers have been heavily subsidized and are selling solar products at unfairly low prices. Perhaps not surprisingly, some Chinese companies have now asked the Chinese government to impose tariffs on imports of American solar products, arguing that U.S.-based producers have been heavily subsidized, too. And just like that, the production of affordable and competitive solar products has become a political liability in the world's two largest producers and consumers of energy.

The success of the entire solar industry hinges on the success of not one country or one company, but global competition and collaboration, which drives efficiency improvements and cost reductions worldwide. If trade barriers are imposed in the U.S., China, or Germany, it could cause a significant increase in the price of solar products and therefore solar electricity, globally. That could cause a further erosion of political support for the solar industry at a critical juncture.

Altogether, a solar trade war could undermine decades of international innovation and stall the global adoption of advanced solar technology.

To read more click here...

Posted by

Unknown

0

comments

Labels:

Asia,

China,

Energy,

Green Energy,

Manufacturing,

United States

Friday 16 December 2011

Solar power generation more powerful in Europe this century

Engineerblogger

Dec 16, 2011

Climate change will increase the amount of electricity generated by solar power in some parts of the world while decreasing it in others. The University of Leeds findings, published in the journal Energy and Environmental Science, have major impacts for countries looking at what type of solar power to build, where to build it and financial rates of return.

One of the study's authors, Professor Piers Forster from the School of Earth and Environment, said: "Climate models are now good enough for making continental scale predictions of several types of change, making them an increasingly useful tool for developing adaption strategies."

The study showed that projected changes in temperature and insolation (sunlight) during 2010-2080 will affect two fast-growing solar technologies: concentrated solar power (CSP) and photovoltaics (PV).

For Europe, there were positive results for both photovoltaics and CSP outputs.

Dr Rolf Crook from the Energy and Resources Research Institute, another of the study's authors, said the relative contribution from changes in insolation and temperature to changes in solar power output depended on the location - for example, in Europe the increased output is largely caused by increased insolation.

In mainland Europe, outputs of CSP, an industry-scale solar power that uses mirrors to focus large amounts of sunlight on a small area, will increase by about 10% (5.5% in the UK).

Outputs of PV, large flat panels that convert sunlight directly into electricity, will increase in mainland Europe by about 3.5% (1.2% in the UK), the study found.

In other parts of the world, PV output will increase by a few percent in China, see little change in Algeria and Australia, and decrease by a few percent in western USA and Saudi Arabia.

CSP output will increase by several percent in China and a few percent in Algeria and Australia, and decrease by a few percent in western USA and Saudi Arabia.

Even an increase of a few percent in CSP outputs in North Africa could have substantial benefits for the two billion euro Desertec (EU-MENA) project, the world's most ambitious solar power plant, incorporating CSP, PV and wind technology across 12 sq kilometres.

Desertec aims to provide half the electricity used by Europe, the Middle East and northern Africa by 2050. Building work is due to start next year in Morocco. A similar concept has been proposed for Australia and Asia.

The study found CSP is more sensitive to climate change than PV.

Dr Crook said the findings would be significant as solar power increasingly contributed to electricity generation in a low-carbon economy.

The findings come at the same time the government withdraws subsidies for households planning to install PV solar panels.

Dr Crook said: "We have shown, perhaps surprisingly, that climate change will have a positive impact on the output of solar power plants in many parts of the world. This further strengthens the case for research and investment in solar power today. Subsidies play a vital role in driving down the cost of solar technology. Cutting subsidies would only have a negative effect."

Regions were selected for the study on account of existing or planned large PV or CSP solar power plants.

The findings are linked only to climate changes impacts; whether countries own or plan to own a large or small quantity of solar power infrastructure was included in the calculations.

Source: University of Leeds

Additional Information:

Dec 16, 2011

Climate change will increase the amount of electricity generated by solar power in some parts of the world while decreasing it in others. The University of Leeds findings, published in the journal Energy and Environmental Science, have major impacts for countries looking at what type of solar power to build, where to build it and financial rates of return.

One of the study's authors, Professor Piers Forster from the School of Earth and Environment, said: "Climate models are now good enough for making continental scale predictions of several types of change, making them an increasingly useful tool for developing adaption strategies."

The study showed that projected changes in temperature and insolation (sunlight) during 2010-2080 will affect two fast-growing solar technologies: concentrated solar power (CSP) and photovoltaics (PV).

For Europe, there were positive results for both photovoltaics and CSP outputs.

Dr Rolf Crook from the Energy and Resources Research Institute, another of the study's authors, said the relative contribution from changes in insolation and temperature to changes in solar power output depended on the location - for example, in Europe the increased output is largely caused by increased insolation.

In mainland Europe, outputs of CSP, an industry-scale solar power that uses mirrors to focus large amounts of sunlight on a small area, will increase by about 10% (5.5% in the UK).

Outputs of PV, large flat panels that convert sunlight directly into electricity, will increase in mainland Europe by about 3.5% (1.2% in the UK), the study found.

In other parts of the world, PV output will increase by a few percent in China, see little change in Algeria and Australia, and decrease by a few percent in western USA and Saudi Arabia.

CSP output will increase by several percent in China and a few percent in Algeria and Australia, and decrease by a few percent in western USA and Saudi Arabia.

Even an increase of a few percent in CSP outputs in North Africa could have substantial benefits for the two billion euro Desertec (EU-MENA) project, the world's most ambitious solar power plant, incorporating CSP, PV and wind technology across 12 sq kilometres.

Desertec aims to provide half the electricity used by Europe, the Middle East and northern Africa by 2050. Building work is due to start next year in Morocco. A similar concept has been proposed for Australia and Asia.

The study found CSP is more sensitive to climate change than PV.

Dr Crook said the findings would be significant as solar power increasingly contributed to electricity generation in a low-carbon economy.

The findings come at the same time the government withdraws subsidies for households planning to install PV solar panels.

Dr Crook said: "We have shown, perhaps surprisingly, that climate change will have a positive impact on the output of solar power plants in many parts of the world. This further strengthens the case for research and investment in solar power today. Subsidies play a vital role in driving down the cost of solar technology. Cutting subsidies would only have a negative effect."

Regions were selected for the study on account of existing or planned large PV or CSP solar power plants.

The findings are linked only to climate changes impacts; whether countries own or plan to own a large or small quantity of solar power infrastructure was included in the calculations.

Source: University of Leeds

Additional Information:

- The article "Climate change impacts on future photovoltaic and concentrated solar power energy output" is published in Energy & Environmental Science.

Posted by

Unknown

2

comments

Labels:

Education,

Environment,

Green Energy,

UK

Nanotechnology to harness the power of hydrogen

Engineerblogger

Dec 16, 2011

The Inorganic Solid State & Materials Research Group is using nanotechnology to try to find a way of turning the universe’s most abundant element, Hydrogen, into a viable source of energy.

When hydrogen is combusted in air, it binds with oxygen to create energy alongside a solitary byproduct: water. Being a relatively cheap and very green source of power, hydrogen is an attractive proposition for companies who are keen to support research into the next generation of fuels and, as a result, the Glasgow researchers have the backing of a consortium of major companies. Indeed, EADS Innovation Works, of which Airbus is a subsidiary, are testing the technology in aeroplanes, with plans in place to build and test a hydrogen fuel cell system in an unmanned aircraft in 2014.

‘The technology that we’re working on at Glasgow is at the forefront of research into sustainable fuels,’ says Glasgow Professor of Inorganic Materials Duncan Gregory, who is head of the research group which is working on hydrogen storage and sustainable energy materials. ‘We are the only group in Scotland working in this area and we have been awarded an Engineering & Physical Sciences Research Council grant of over £3 million to work with the Universities of St Andrews, Strathclyde and Newcastle on a four-year project to develop a new hybrid system combining hydrogen storage, fuel cells and lithium batteries.

‘This is an exciting time to be working in this area, but it is very challenging work.’

Trying to store hydrogen is notoriously difficult; problems can occur in attempting to keep the substance in a manageable form useful in applications such as cars or aeroplanes. In order for hydrogen to be a feasible fuel source for a vehicle, it needs to be stored safely, occupy a relatively small volume and present a minimal burden in terms of weight. Finding a way of storing hydrogen that fulfils all these necessary requirements has so far proved so difficult that using hydrogen as a fuel might still seem a long way off.

The most feasible option is storing hydrogen as a solid; this involves binding the hydrogen atoms to another substance that would act like a sponge, soaking it up; the hydrogen could then be safely stored until it was needed. Until now the problem with this method was that existing materials either bonded to the hydrogen too strongly or not strongly enough.

To overcome this problem, the team at Glasgow are using nanotechnology to build a new substance to their own specifications, which is capable of trapping and releasing hydrogen only under the right conditions.

‘We’re approaching this by trying to develop some kind of nanomaterial that fits our purpose,’ says Professor Gregory. ‘The reason that we are doing this is that when it comes to solid-state storage there are two extremes; on the one hand you can have porous, spongelike solids that are easy to get hydrogen to bind to, but they also release it too easily; on the other hand, you can have materials that hold the hydrogen too well, meaning that you have to heat the material up to get it to release again and this requires energy.

‘So what we need is some kind of solution that’s in the middle of these two extremes and we think nanofabrication is the way to do this.’

Using the state-of-the-art synthesis techniques and facilities at the University’s Kelvin Nanocharacterisation Centre, the group can begin to build compounds to meet their needs and make the reactions that bind hydrogen to solids in a fuel cell much easier to control.

‘We have a patent on a nanostructured material, based on lithium nitride, and when you react this with hydrogen it goes through two stages whereupon hydrogen becomes bonded in the structure,’ says Professor Gregory.

‘There are several ways in which making a nanostructured version of this material improves its performance: for example, we can get reactions to happen faster because the nanomaterials have a high surface area. However, we also want to see if we can apply our techniques to create other materials that may have different and useful properties, and there are companies backing us who are interested in the work we are doing here at the University.’

Indeed, the work done by university research groups such as Glasgow’s are opening the gates to a new world of energy production. Although we are only at the research stage, the potential of this technology is huge, as harnessing the potential of hydrogen may be the beginning of the end of our reliance on fossil fuels and a step towards a cleaner and greener future.

Source: Glasgow University

Dec 16, 2011

The Inorganic Solid State & Materials Research Group is using nanotechnology to try to find a way of turning the universe’s most abundant element, Hydrogen, into a viable source of energy.

When hydrogen is combusted in air, it binds with oxygen to create energy alongside a solitary byproduct: water. Being a relatively cheap and very green source of power, hydrogen is an attractive proposition for companies who are keen to support research into the next generation of fuels and, as a result, the Glasgow researchers have the backing of a consortium of major companies. Indeed, EADS Innovation Works, of which Airbus is a subsidiary, are testing the technology in aeroplanes, with plans in place to build and test a hydrogen fuel cell system in an unmanned aircraft in 2014.

‘The technology that we’re working on at Glasgow is at the forefront of research into sustainable fuels,’ says Glasgow Professor of Inorganic Materials Duncan Gregory, who is head of the research group which is working on hydrogen storage and sustainable energy materials. ‘We are the only group in Scotland working in this area and we have been awarded an Engineering & Physical Sciences Research Council grant of over £3 million to work with the Universities of St Andrews, Strathclyde and Newcastle on a four-year project to develop a new hybrid system combining hydrogen storage, fuel cells and lithium batteries.

‘This is an exciting time to be working in this area, but it is very challenging work.’

Trying to store hydrogen is notoriously difficult; problems can occur in attempting to keep the substance in a manageable form useful in applications such as cars or aeroplanes. In order for hydrogen to be a feasible fuel source for a vehicle, it needs to be stored safely, occupy a relatively small volume and present a minimal burden in terms of weight. Finding a way of storing hydrogen that fulfils all these necessary requirements has so far proved so difficult that using hydrogen as a fuel might still seem a long way off.

The most feasible option is storing hydrogen as a solid; this involves binding the hydrogen atoms to another substance that would act like a sponge, soaking it up; the hydrogen could then be safely stored until it was needed. Until now the problem with this method was that existing materials either bonded to the hydrogen too strongly or not strongly enough.

To overcome this problem, the team at Glasgow are using nanotechnology to build a new substance to their own specifications, which is capable of trapping and releasing hydrogen only under the right conditions.

‘We’re approaching this by trying to develop some kind of nanomaterial that fits our purpose,’ says Professor Gregory. ‘The reason that we are doing this is that when it comes to solid-state storage there are two extremes; on the one hand you can have porous, spongelike solids that are easy to get hydrogen to bind to, but they also release it too easily; on the other hand, you can have materials that hold the hydrogen too well, meaning that you have to heat the material up to get it to release again and this requires energy.

‘So what we need is some kind of solution that’s in the middle of these two extremes and we think nanofabrication is the way to do this.’

Using the state-of-the-art synthesis techniques and facilities at the University’s Kelvin Nanocharacterisation Centre, the group can begin to build compounds to meet their needs and make the reactions that bind hydrogen to solids in a fuel cell much easier to control.

‘We have a patent on a nanostructured material, based on lithium nitride, and when you react this with hydrogen it goes through two stages whereupon hydrogen becomes bonded in the structure,’ says Professor Gregory.

‘There are several ways in which making a nanostructured version of this material improves its performance: for example, we can get reactions to happen faster because the nanomaterials have a high surface area. However, we also want to see if we can apply our techniques to create other materials that may have different and useful properties, and there are companies backing us who are interested in the work we are doing here at the University.’

Indeed, the work done by university research groups such as Glasgow’s are opening the gates to a new world of energy production. Although we are only at the research stage, the potential of this technology is huge, as harnessing the potential of hydrogen may be the beginning of the end of our reliance on fossil fuels and a step towards a cleaner and greener future.

Source: Glasgow University

Posted by

Unknown

0

comments

Labels:

Aircraft,

EADS,

Education,

Energy,

Green Energy,

Research and Development,

Technology,

UK

The world’s largest plant producing high capacity lithium-ion batteries has been launched in Novosibirsk region

Engineerblogger

Dec 16, 2011

The world’s largest plant producing high capacity lithium-ion batteries has been launched in Novosibirsk region today. The plant belongs to the LIOTECH Company – a joint venture between Russian Corporation of Nanotechnologies (RUSNANO) and the International holding Thunder Sky Limited. The total investment in the project has amounted more than 13,5 billion rubles. The plant which overall area of production facility is over 40 000 sq. m. has been built in a record-breaking period, just in 9 months.

Alexey Homlyaskiy, the Deputy Governor of Novosibirsk Region, Anatoly Chubais, the Chairman the Board of RUSNANO, Alexander Erokhin, the CEO of LIOTECH LLC took part in the ceremony of opening of a new plant.

Using ecofriendly nanostructured cathode lithium – ferrum – phosphate material (LiFePO4), the LIOTECH Plant will output batteries with different nominal capacity: 200, 300 and 700 A*hr. As of today, this material allows to achieve the best performance of the batteries within the frame of their industrial manufacturing.

The planned capacity of new plant will amount over 1 GWh or about 1 mln. batteries per year. This enables to equip with the batteries about 5, 000 electric buses annually.

The LIOTECH lithium-ion batteries differ with high-power density, do not need secondary service and have a wide temperature range of usage. These characteristics enable us to use them widely in electrical transport, as well as in power industry as energy storage devices and uninterruptible power supplies. Moreover, after batteries have been used in electric transport, they still can be utilized as accumulators in power industry during 10-15 years more. Also, it is necessary to note that recycling of such a type of accumulators is completely safe for environment.

The fact that the LIOTECH LLC has already concluded delivery contracts for batteries before the manufacturing has been launched, emphasizes being in demand of a new product. One of the main consumers of new batteries in Russia will be the MOBEL LLC; 3 billion rubles contract has already been sighed with this company.

"The new plant is a successful example of foreign high-technologies’ transfer, allowing to create a modern manufacture, in which, after reaching full production capacity over 500 people will be employed. By implementing the program of import substitution, we will create a whole cluster of new high-tech manufacturing of related materials and components as well as an Engineering Center ", - emphasizes Sergey Polikarpov, RUSNANO Managing Director.

“Implementation of public electric vehicle equipped with lithium-ion batteries of our production will significantly improve the environment situation in large cities of Russia. Utilizing of batteries together with alternative energy sources will boost the development of "green technologies" and increase the energy efficiency of the economy of the Russian Federation. Russian Railway Company and Moscow underground rapid transport system, electricity supply network and power generation companies, military industrial enterprises as well as housing and communal services, telecommunication companies have already shown a great interest towards energy storage units of our batteries”, - notes LIOTECH CEO, Alexander Erokhin.

Source: Liotech

Dec 16, 2011

The world’s largest plant producing high capacity lithium-ion batteries has been launched in Novosibirsk region today. The plant belongs to the LIOTECH Company – a joint venture between Russian Corporation of Nanotechnologies (RUSNANO) and the International holding Thunder Sky Limited. The total investment in the project has amounted more than 13,5 billion rubles. The plant which overall area of production facility is over 40 000 sq. m. has been built in a record-breaking period, just in 9 months.

Alexey Homlyaskiy, the Deputy Governor of Novosibirsk Region, Anatoly Chubais, the Chairman the Board of RUSNANO, Alexander Erokhin, the CEO of LIOTECH LLC took part in the ceremony of opening of a new plant.

Using ecofriendly nanostructured cathode lithium – ferrum – phosphate material (LiFePO4), the LIOTECH Plant will output batteries with different nominal capacity: 200, 300 and 700 A*hr. As of today, this material allows to achieve the best performance of the batteries within the frame of their industrial manufacturing.

The planned capacity of new plant will amount over 1 GWh or about 1 mln. batteries per year. This enables to equip with the batteries about 5, 000 electric buses annually.

The LIOTECH lithium-ion batteries differ with high-power density, do not need secondary service and have a wide temperature range of usage. These characteristics enable us to use them widely in electrical transport, as well as in power industry as energy storage devices and uninterruptible power supplies. Moreover, after batteries have been used in electric transport, they still can be utilized as accumulators in power industry during 10-15 years more. Also, it is necessary to note that recycling of such a type of accumulators is completely safe for environment.

The fact that the LIOTECH LLC has already concluded delivery contracts for batteries before the manufacturing has been launched, emphasizes being in demand of a new product. One of the main consumers of new batteries in Russia will be the MOBEL LLC; 3 billion rubles contract has already been sighed with this company.

"The new plant is a successful example of foreign high-technologies’ transfer, allowing to create a modern manufacture, in which, after reaching full production capacity over 500 people will be employed. By implementing the program of import substitution, we will create a whole cluster of new high-tech manufacturing of related materials and components as well as an Engineering Center ", - emphasizes Sergey Polikarpov, RUSNANO Managing Director.

“Implementation of public electric vehicle equipped with lithium-ion batteries of our production will significantly improve the environment situation in large cities of Russia. Utilizing of batteries together with alternative energy sources will boost the development of "green technologies" and increase the energy efficiency of the economy of the Russian Federation. Russian Railway Company and Moscow underground rapid transport system, electricity supply network and power generation companies, military industrial enterprises as well as housing and communal services, telecommunication companies have already shown a great interest towards energy storage units of our batteries”, - notes LIOTECH CEO, Alexander Erokhin.

Source: Liotech

Posted by

Unknown

0

comments

Labels:

BRIC,

Green Energy,

Manufacturing,

Materials,

Nanotechnology,

Russia

‘Fingerprinting’ method tracks mercury emissions from coal-fired power plant

University of Michigan

Dec 15, 2011

For the first time, the chemical "fingerprints" of the element mercury have been used by University of Michigan researchers to directly link environmental pollution to a specific coal-burning power plant.

The primary source of mercury pollution in the atmosphere is coal combustion. The U-M mercury-fingerprinting technique – which has been under development for a decade – provides a tool that will enable researchers to identify specific sources of mercury pollution and determine how much of it is being deposited locally.

"We see a specific, distinct signature to the mercury that's downwind of the power plant, and we can clearly conclude that mercury from that power plant is being deposited locally," said Joel Blum, the John D. MacArthur Professor of Earth and Environmental Sciences.

Blum is co-author of a paper published online Dec. 13 in the journal Environmental Science & Technology. The lead author of the paper is U-M doctoral candidate Laura Sherman, who works with Blum.

"This allows us to directly fingerprint and track the mercury that's coming from a power plant, going into a local lake, and potentially impacting the fish that people are eating," said Sherman, who has worked on the project for four years.

Mercury is a naturally occurring element, but some 2,000 tons are emitted to the atmosphere each year from human-generated sources such as incinerators, chlorine-producing plants and coal-fired power plants.

This mercury is deposited onto land and into water, where microorganisms convert some of it to methylmercury, a highly toxic form that builds up in fish and the animals that eat them. In wildlife, exposure to methylmercury can interfere with reproduction, growth, development and behavior---and may even cause death.

Effects on humans include damage to the central nervous system, heart and immune system. The developing brains of fetuses and young children are especially vulnerable.

Among mercury researchers, there has been a long-running debate about how much mercury pollution is deposited near emissions sites and how much is lofted high into the atmosphere, where it becomes part of a global mercury reservoir comprised of emissions from countless mercury sources around the world. Some researchers have argued that there is limited local mercury deposition and that most human mercury emissions end up in the global atmospheric pool.

But results from the latest study by Sherman and her colleagues prove that mercury is deposited locally near coal-fired power plants and doesn't simply vanish into a global pool high in the sky. "It makes it hard to argue that there's no local deposition when we're seeing such unique signatures like this," Sherman said.

The mercury fingerprinting technique relies on a natural phenomenon called isotopic fractionation. All atoms of a particular element contain the same number of protons in their nuclei. However, a given element will have various forms, known as isotopes, each with a different number of neutrons in its nucleus.

Mercury has seven stable (non-radioactive) isotopes. During isotopic fractionation, different mercury isotopes react to form new compounds at slightly different rates. Sherman and her colleagues measured a type of isotopic fractionation called mass-dependent fractionation (MDF), in which the different reaction rates depend on the masses of the isotopes.

Using MDF, the researchers compared the ratio of different mercury isotopes in their samples. That ratio provides a unique chemical signature, or fingerprint, that can be used as a diagnostic tool to compare environmental samples from various locations.

The latest study involved collecting daily rainfall samples in July 2009 from four sites surrounding a coal-fired power plant in Crystal River, Fla., which is on the Gulf of Mexico coast roughly 80 miles north of Tampa. To read more click here...

Dec 15, 2011

|

| A coal-fired power plant in Ohio. |

For the first time, the chemical "fingerprints" of the element mercury have been used by University of Michigan researchers to directly link environmental pollution to a specific coal-burning power plant.

The primary source of mercury pollution in the atmosphere is coal combustion. The U-M mercury-fingerprinting technique – which has been under development for a decade – provides a tool that will enable researchers to identify specific sources of mercury pollution and determine how much of it is being deposited locally.

"We see a specific, distinct signature to the mercury that's downwind of the power plant, and we can clearly conclude that mercury from that power plant is being deposited locally," said Joel Blum, the John D. MacArthur Professor of Earth and Environmental Sciences.

Blum is co-author of a paper published online Dec. 13 in the journal Environmental Science & Technology. The lead author of the paper is U-M doctoral candidate Laura Sherman, who works with Blum.

"This allows us to directly fingerprint and track the mercury that's coming from a power plant, going into a local lake, and potentially impacting the fish that people are eating," said Sherman, who has worked on the project for four years.

Mercury is a naturally occurring element, but some 2,000 tons are emitted to the atmosphere each year from human-generated sources such as incinerators, chlorine-producing plants and coal-fired power plants.

This mercury is deposited onto land and into water, where microorganisms convert some of it to methylmercury, a highly toxic form that builds up in fish and the animals that eat them. In wildlife, exposure to methylmercury can interfere with reproduction, growth, development and behavior---and may even cause death.

Effects on humans include damage to the central nervous system, heart and immune system. The developing brains of fetuses and young children are especially vulnerable.

Among mercury researchers, there has been a long-running debate about how much mercury pollution is deposited near emissions sites and how much is lofted high into the atmosphere, where it becomes part of a global mercury reservoir comprised of emissions from countless mercury sources around the world. Some researchers have argued that there is limited local mercury deposition and that most human mercury emissions end up in the global atmospheric pool.

But results from the latest study by Sherman and her colleagues prove that mercury is deposited locally near coal-fired power plants and doesn't simply vanish into a global pool high in the sky. "It makes it hard to argue that there's no local deposition when we're seeing such unique signatures like this," Sherman said.

The mercury fingerprinting technique relies on a natural phenomenon called isotopic fractionation. All atoms of a particular element contain the same number of protons in their nuclei. However, a given element will have various forms, known as isotopes, each with a different number of neutrons in its nucleus.

Mercury has seven stable (non-radioactive) isotopes. During isotopic fractionation, different mercury isotopes react to form new compounds at slightly different rates. Sherman and her colleagues measured a type of isotopic fractionation called mass-dependent fractionation (MDF), in which the different reaction rates depend on the masses of the isotopes.

Using MDF, the researchers compared the ratio of different mercury isotopes in their samples. That ratio provides a unique chemical signature, or fingerprint, that can be used as a diagnostic tool to compare environmental samples from various locations.

The latest study involved collecting daily rainfall samples in July 2009 from four sites surrounding a coal-fired power plant in Crystal River, Fla., which is on the Gulf of Mexico coast roughly 80 miles north of Tampa. To read more click here...

Posted by

Unknown

0

comments

Labels:

Education,

Environment,

Research and Development

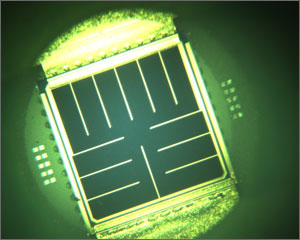

Discovery of a ‘Dark State’ Could Mean a Brighter Future for Solar Energy

Engineerblogger

Dec 16, 2011

The efficiency of conventional solar cells could be significantly increased, according to new research on the mechanisms of solar energy conversion led by chemist Xiaoyang Zhu at The University of Texas at Austin.

Zhu and his team have discovered that it's possible to double the number of electrons harvested from one photon of sunlight using an organic plastic semiconductor material.

"Plastic semiconductor solar cell production has great advantages, one of which is low cost," said Zhu, a professor of chemistry. "Combined with the vast capabilities for molecular design and synthesis, our discovery opens the door to an exciting new approach for solar energy conversion, leading to much higher efficiencies."

Zhu and his team published their groundbreaking discovery Dec. 16 in Science.

The maximum theoretical efficiency of the silicon solar cell in use today is approximately 31 percent, because much of the sun's energy hitting the cell is too high to be turned into usable electricity. That energy, in the form of "hot electrons," is instead lost as heat. Capturing hot electrons could potentially increase the efficiency of solar-to-electric power conversion to as high as 66 percent.

Zhu and his team previously demonstrated that those hot electrons could be captured using semiconductor nanocrystals. They published that research in Science in 2010, but Zhu says the actual implementation of a viable technology based on that research is very challenging.

"For one thing," said Zhu, "that 66 percent efficiency can only be achieved when highly focused sunlight is used, not just the raw sunlight that typically hits a solar panel. This creates problems when considering engineering a new material or device."

To circumvent that problem, Zhu and his team have found an alternative. They discovered that a photon produces a dark quantum "shadow state" from which two electrons can then be efficiently captured to generate more energy in the semiconductor pentacene.

Zhu said that exploiting that mechanism could increase solar cell efficiency to 44 percent without the need for focusing a solar beam, which would encourage more widespread use of solar technology.

The research team was spearheaded by Wai-lun Chan, a postdoctoral fellow in Zhu’s group, with the help of postdoctoral fellows Manuel Ligges, Askat Jailaubekov, Loren Kaake and Luis Miaja-Avila. The research was supported by the National Science Foundation and the Department of Energy.

Source: University of Texas at Austin

Additional Information:

Dec 16, 2011

|

| Professor Xiaoyang Zhu |

The efficiency of conventional solar cells could be significantly increased, according to new research on the mechanisms of solar energy conversion led by chemist Xiaoyang Zhu at The University of Texas at Austin.

Zhu and his team have discovered that it's possible to double the number of electrons harvested from one photon of sunlight using an organic plastic semiconductor material.

"Plastic semiconductor solar cell production has great advantages, one of which is low cost," said Zhu, a professor of chemistry. "Combined with the vast capabilities for molecular design and synthesis, our discovery opens the door to an exciting new approach for solar energy conversion, leading to much higher efficiencies."

Zhu and his team published their groundbreaking discovery Dec. 16 in Science.

The maximum theoretical efficiency of the silicon solar cell in use today is approximately 31 percent, because much of the sun's energy hitting the cell is too high to be turned into usable electricity. That energy, in the form of "hot electrons," is instead lost as heat. Capturing hot electrons could potentially increase the efficiency of solar-to-electric power conversion to as high as 66 percent.

Zhu and his team previously demonstrated that those hot electrons could be captured using semiconductor nanocrystals. They published that research in Science in 2010, but Zhu says the actual implementation of a viable technology based on that research is very challenging.

"For one thing," said Zhu, "that 66 percent efficiency can only be achieved when highly focused sunlight is used, not just the raw sunlight that typically hits a solar panel. This creates problems when considering engineering a new material or device."

To circumvent that problem, Zhu and his team have found an alternative. They discovered that a photon produces a dark quantum "shadow state" from which two electrons can then be efficiently captured to generate more energy in the semiconductor pentacene.

Zhu said that exploiting that mechanism could increase solar cell efficiency to 44 percent without the need for focusing a solar beam, which would encourage more widespread use of solar technology.

The research team was spearheaded by Wai-lun Chan, a postdoctoral fellow in Zhu’s group, with the help of postdoctoral fellows Manuel Ligges, Askat Jailaubekov, Loren Kaake and Luis Miaja-Avila. The research was supported by the National Science Foundation and the Department of Energy.

Source: University of Texas at Austin

Additional Information: