National Renewable Energy Laboratory (NREL)

Sept 29, 2011

Ink can cause a mess, but the Silicon Ink developed by Innovalight behaves itself so well that when it is added to a solar cell it doesn't clump or spill, instead it boosts the cell's power by a startling, profit-boosting 5 to 7 percent.

Both solar cells and T-shirts can be enhanced with a screen printer, some ink and a squeegee.

But it takes a real special ink to suspend silicon nanoparticles so uniformly that it can lay down the precise microns-thick lines needed to dope the silicon emitter exactly under the front metal contacts. Those contacts make a solar cell work.

Innovalight, a small start-up from Sunnyvale, Calif., came up with an ingenious way to suspend silicon in a solution without the tiny particles glomming onto one another or sinking to the bottom of the container.

But could that Silicon Ink prove useful for solar cells?

Researchers at the U.S. Department of Energy's (DOE) National Renewable Energy Laboratory (NREL) proved that the answer is "yes." And the winners could be the solar cell industry and the environment, because Silicon Ink, when added to the manufacturing process, can make solar cells more efficient and save a large plant hundreds of millions of dollars each year.

NREL and Innovalight shared a coveted R&D 100 award for 2011 for the Silicon Ink technology. Given by R&D 100 Magazine, the R&D 100 awards are referred to in the industry as the "Oscars of Invention." Silicon Ink's ability to boost efficiency in such a low-cost way prompts some in the industry to label it "liquid gold."

Impurities in Silicon Are Key to Making Contacts, Making Electricity

Silicon is the key ingredient in most of the billions of solar cells made each year worldwide.

Dopants or impurities are used to change the conductivity of silicon and to create the internal electric fields that are needed to turn photons into electrons and thus into electricity. One of the great challenges is to distribute the exact concentrations of dopants in precisely the correct locations throughout the device.

Innovalight scored big with Silicon Ink because it found a way to suspend silicon nanoparticles evenly in a solution. Those silicon nanoparticles contain dopant atoms that can be driven into silicon solar cell to form a selective emitter.

What Innovalight's potential customers and investors wanted to know was whether the ink can deliver high concentrations of dopants to extremely localized regions of the emitter and increase a solar cell's efficiency.

NREL Senior Scientists Kirstin Alberi and David Young listened to what Innovalight wanted to prove and then suggested some experiments that could help them prove it.

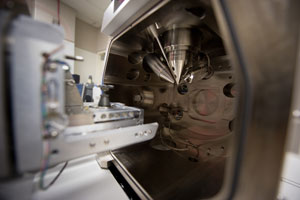

"The question was, 'can you print this ink in very well defined lines and drive in dopants only in the material underneath the lines to create a well-defined selective emitter," said Alberi, who began at NREL three years ago as a post-doctorate researcher. If so, the increased concentration of dopants right under the contacts would lower the resistance at the metal contact, while the rest of the cell contained low-doped silicon — and that would mean jumps in efficiency and savings of huge amounts of money.

"On some level, you want the emitter to be highly doped so it makes a better contact with the metal," Alberi said. "But if it's too heavily doped elsewhere, that's bad."

That's why a "selective emitter" that is heavily doped only in precise portions of a solar cell is such a promising technology.

To read more click here...

0 comments:

Post a Comment