Jan 12, 2012

Polymer nanocomposites represent a new class of multiphase materials containing dispersion of nano-sized filler materials such as nanoparticles, nanoclays, nanotubes, nanofibers etc. within the polymer matrices. Owing to their nanoscale size features and very high surface-to-volume ratios, they possess unique combination of multifunctional properties not shared by their more conventional composite counterparts reinforced with micro-sized fillers. These multifunctional nanocomposites not only exhibit excellent mechanical properties, but also display outstanding combination of optical, electrical, thermal, magnetic and other physico-chemical properties. It is believed that the molecular level interactions between the nanoparticles and polymer matrices along with the presence of very high nanoparticle-polymer interfacial area play a major role in influencing the physical and mechanical properties of nanocomposites. The major development in this field has occurred over the last two decades.

This article summarizes the progress, products outlook, advantages, and limitations of nanocomposites in the automotive industry.

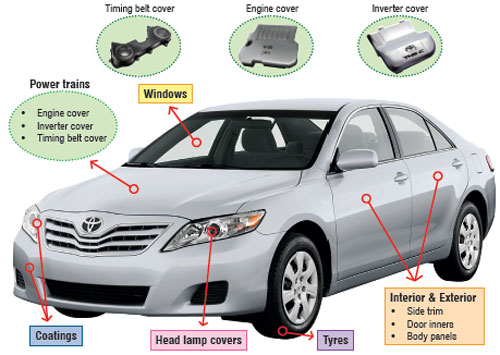

Nanocomposites are an emerging class of polymeric materials exhibiting excellent mechanical properties, enhanced modulus and dimensional stability, flame retardancy, improved scratch and mar resistance, superior thermal and processing properties, reduced warpage of components and enhanced impact resistance making them suitable to replace metals in automotive and other applications. The key drivers for the use of polymer nanocomposite-enabled parts in the automotive industry are reduction in vehicle's weight, improved engine efficiency (fuel saving), reduction in CO2 emissions and superior performance (greater safety, increased comfort and better driveability). Fig. 1 illustrates the usage of polymer nanocomposites parts.

|

| Fig 1: Illustration of the usage of polymer nanocomposites parts. |

The commercialization of polymer nanocomposites started in 1991 when Toyota Motor Co. first introduced nylon-6/clay nanocomposites in the market to produce timing belt covers as a part of the engine for their Toyota Camry cars, in collaboration with Ube industries in 1991. At about the same period, Unitika Co. of Japan introduced nylon-6 nanocomposite for engine covers on Mitsubishi GDI engines manufactured by injection moulding, the product is said to offer a 20% weight reduction and excellent surface finish. In 2002, General Motors launched a step-assist automotive component made of polyolefin reinforced with 3% nanoclays, in collaboration with Basell (now LyondellBasell Industries) for GM's Safari and Chevrolet Astro vans, followed by the application of these nanocomposites in the doors of Chevrolet Impalas.

To read more click here...

0 comments:

Post a Comment