March 16, 2012

|

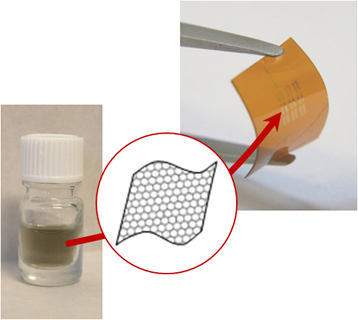

| Single-layer graphene in solution used for making flexible transistors on a polyimide substrate (a sheet of thermostable polymer). © CEA |

Making electronic components using graphene, a material composed of a single layer of carbon atoms, is one of today's major technological challenges. Researchers hope to harness the outstanding electron mobility of graphene and also use the material to design low-cost, flexible electronics. Research teams from CEA(1), CNRS(2), Université de Lille 1(2) and Northwestern University(3) have come up with a novel process for manufacturing transistors that combine flexibility and electron mobility and are capable of working at very high frequencies in the GHz range. The process uses a form of graphene in solution that is compatible with printing techniques. Electronic components such as these should lead to the development of high-performance electronic circuits built into everyday objects.

The results appeared in the journal Nano Letters on March 14, 2012.

Graphene, a material that consists of a single layer of hexagonal carbon atoms, has some outstanding properties. In particular, its high electron mobility is expected to help electronic components perform at very high frequencies. Its mechanical properties also make it flexible. These two properties – electron mobility and flexibility – could be usefully employed to make electronic components and circuits for various applications, such as developing flexible screens and very high-performance transistors and electronic components at low cost.

Several methods of graphene synthesis are currently available. One of them involves producing graphene as a solution of tiny particles, a few hundred nanometers in diameter, which are stabilized in water by surfactants(4). The method of synthesis used to obtain the resulting “conductive ink” makes it possible to select only single-layer sheets that exhibit remarkable electronic properties(5) (instead of a combination of single-layer and multilayer graphene). Another specific feature is that components can be produced on a very wide range of media, including glass, paper or organic substrates.

The research teams from CEA, CNRS, Université de Lille 1 and Northwestern University developed the first ever process for making flexible transistors from solubilized graphene on polyimide (a thermostable polymer) substrates. They then made an in-depth study of high-frequency performance of these transistors.

In the process developed by the researchers, sheets of graphene in solution are deposited on the substrate with an alternating electric field applied between electrodes made in advance. This technique, known as dielectrophoresis or DEP, is used to guide the graphene deposition process so as to obtain a high density of deposited sheets in certain spots. This density is essential for achieving outstanding high-frequency performance. The charge mobility in the transistors is in the region of 100 cm2/V.s, a far higher value than that obtained with semiconductor molecules or polymers. These transistors thus achieve very high frequencies – around 8 GHz – a level of performance never before obtained in organic electronics!

The results show that “conductive ink” graphene is a highly competitive material for making flexible electronic applications in a high-frequency range (GHz) that is completely out of reach for conventional organic semiconductors. This new generation of transistors offers excellent prospects for many applications, including flexible screens (folding or roll-up), electronic devices built into fabrics or other everyday objects, such as RFID(6) tags, capable of processing and transmitting information.

Source: Centre national de la recherche scientifique (CNRS)

Additional Information:

0 comments:

Post a Comment